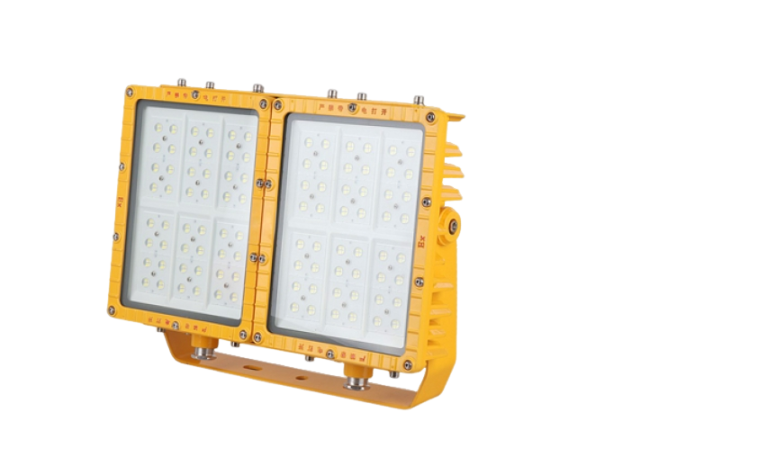

Fire explosions proof led lights: coal mine safety lighting fundamental technology analysis and innovative practice

First, why must coal mines use fire and explosion-proof lighting?

Coal mine underground environment is complex, gas [methane], coal dust and other flammable and explosive substances are widely available, the traditional lighting equipment is very easy due to sparks or high temperature triggered by an explosion.

The fireproof and explosion-proof lighting is approved for explosion-proof or intrinsically safe design, which completely isolates the circuit from the external explosive environment, fundamentally eliminating the risk of spark leakage, and safeguarding the life safety of miners and production continuity.

In addition to this, its high protection level [IP65 and above] can withstand underground humidity, dust, mechanical shock, to ensure long-term stable operation.

Second, Fire explosions proof led lights in the coal mine core technology breakthroughs

LED light source and efficient heat dissipation technology using high-power LED module, light efficiency of up to 150lm / W or more, compared with the traditional light source energy saving 70%.

Combined with aluminum alloy cooling fins and heat pipe technology, high-speed heat export, to avoid lamps and lanterns due to high-temperature failure, extend the service life to more than 50,000 hours.

Explosion-proof structure design approves the separate cavity isolation technology, the power supply, light source and wiring part of the independent sealing, even if the internal components fail, will not ignite the external gas or coal dust.

Explosion-proof marking ExdI in line with GB3836, ATEX guidelines, to meet the mandatory safety certification of coal mines.

Intelligent control and emergency function with integrated IoT module helps to remotely monitor the status of the lamps, brightness adjustment and fault alarm. Built-in emergency power supply in case of power failure can maintain 1-3 hours of lighting, which can buy time for the evacuation of underground personnel.

Third. Typical application scenes of coal mine Fire explosions proof led lights

1. underground tunnel main lighting: covering the mining face to the transportation channel, supplying non-glare, uniform lighting environment, avoiding visual fatigue triggering operational errors.

2. Gas extraction area: the lamp shell adopts corrosion-resistant alloy, which is resistant to the erosion of high concentration of methane and acidic gases and ensures long-term reliability.

3. Ventilation and drainage system: in the humid, dusty pump room and fan room, the IP67 protection of the lamps and lanterns can prevent water vapor infiltration and ensure the safety of equipment inspection.

Fourth, Fire explosions proof led lights four major advantages

1. safety compliance: approved by the national mining product safety mark certification [MA] and international ATEX/IECEx guidelines, to avoid legal risks.

2. energy saving and consumption reduction: LED technology combined with intelligent dimming, comprehensive energy consumption by 60%, to help coal mines to implement green production intentions.

3. Low maintenance cost: modular design helps high-speed replacement of light source or driver, reducing downtime; long-life design reduces the frequency of spare parts procurement.

4. Environmental adaptability: resistant to extreme temperatures from -40℃ to +60℃, anti-vibration performance up to 5G, adapting to the complex working conditions underground.

Fifth, how to choose the right coal mine fire and explosion-proof lighting?

1. Define the explosion-proof level: according to the hazardous level of the operation area [such as Zone 0/1/2] to choose ExdI or Exde IIB products. 2.

2. Pay attention to the protection performance: give priority to IP66/IP67 protection level, to ensure that the waterproof and dust-proof.

3. Verify the qualification of the supplier: Confirm that the manufacturer has the explosion-proof certificate, coal mine safety certification [such as MA] and customized service capabilities.

Sixth. Installation and maintenance guidelines

1. Professional installation: operated by a licensed electrician to avoid misplaced seals or wiring errors resulting in explosion-proof failure.

2. Regular inspection: clean up the surface of the lamps and lanterns every month, check whether the shell is deformed or rusted, and replace the aging seals as soon as possible.

3. Strictly prohibit illegal operation: prohibit disassembly with electricity or use of non-original accessories to prevent damage to the explosion-proof structure.

FAQ: Coal mine Fire explosions proof led lights common problems

Q1:Difference between explosion-proof [Exd] and safety-increasing [Exe] lamps and lanterns?

A1:Explosion-isolated type is approved to seal the structure to contain the internal explosion, and is suitable for high hazardous area [Zone 1];

The increased safety type is approved to enhance the safety of components to prevent sparks, and is mostly used in Zone 2 environments.

Q2:Do I need to replace the lamps regularly?

A2: LED light source life of more than 50,000 hours, often do not need to be replaced frequently, but need to test the circuit sealing every 2 years.

Q3: Does the intelligent control system increase the cost?

A3:Initial investment is slightly higher, but can be approved to improve energy consumption, fault warning to reduce long-term operation and maintenance costs, the return on investment cycle of about 1.5 years.

Q4:How to deal with waste lamps and lanterns?

A4:Contact professional recycling organizations to deal with, prohibit arbitrary disassembly to avoid residual harmful substances polluting the environment.